Rotocast Machine

Rotocast Machine

In Stock: 0

Couldn't load pickup availability

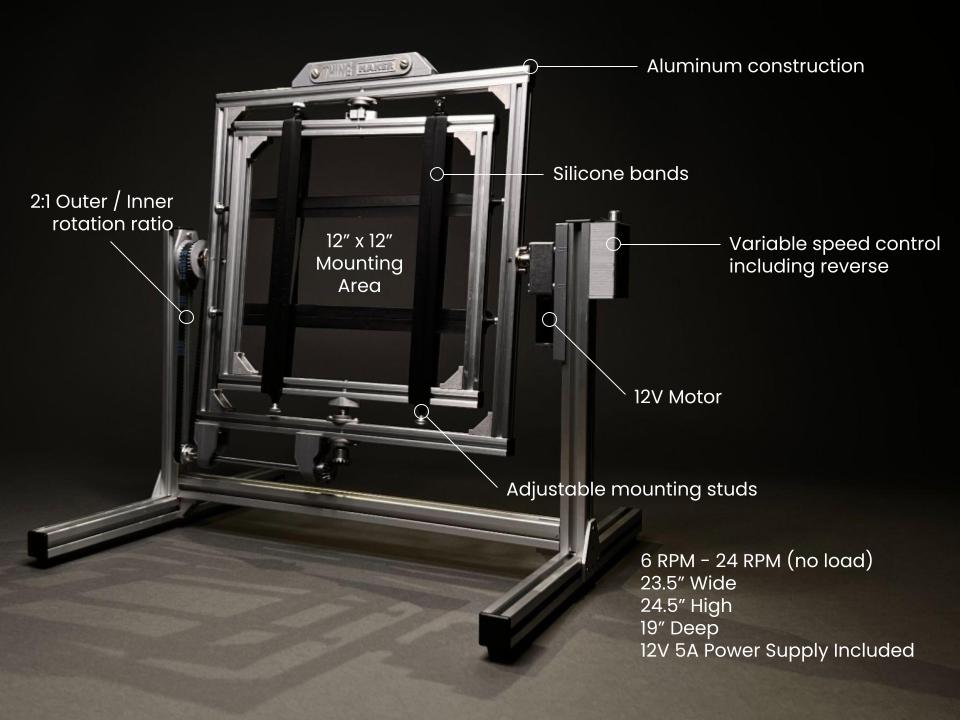

Custom Designed and Built Rotocast Machine

This has been replaced by the NEW Rotocast Digital

https://hackmakemod.com/products/rotocast-digital

2:1 Outer / Inner Rotation Ratio

12” x 12” Mounting Area

Adjustable Mounting Studs

Silicone Mounting Bands

90% Assembled

Motorized with variable speed and direction

12V Motor

5A Power Supply

Aluminum Construction

6 RPM - 24 RPM (No Load)

Overall dimensions: 23.5” W x 24.5” H x 19” D

Rotocasting, also known as rotational casting or rotomolding, is a process used to produce hollow castings. It involves a liquid material like resin or chocolate and then introducing it into a mold that is mounted on a rotating machine. As the mold rotates, the material is evenly distributed around the inner surface of the mold, forming a uniform, hollow part.

The rotocasting process is used to produce a wide range of products, including toys, models, and other hollow parts. It is often used for large or complex-shaped parts that would be difficult to produce using traditional molding methods. One of the main advantages of rotocasting is that it allows manufacturers to produce parts with consistent wall thickness and minimal surface imperfections. It is also a relatively low-cost manufacturing process compared to other methods.

The whole reason you need a rotocast machine is to create hollow, strong and lightweight copies of your sculptures. This will not only save you money (less material) but will also give you a much nicer result! Let’s not forget about freeing you up to walk away and work on other things as the machine does the work! Once you figure out the proper amount of resin for your piece (too much will result in heavy spots in your casting, while too little will be thin and fragile), simply fill and close your mold, mount it in the silicone holding bands (silicone is great because any leaked resin peels right off) and you are up and running! Usually a slower speed is ideal but again you may need to do a test to dial it in.

My development partner, John Pinkerton, has been working with molds and resin castings since the 1990s. He is well known for his toy designs and has been struggling to find a good reliable solution for turning his molds...

"This machine is very capable of turning heavy molds, but as a general rule, the heavier the mold, the more centered and balanced the mold needs to be! I’ve logged hundreds of hours on this machine already for my own work so I am very confident in its abilities. The inner frame (where you will mount your mold) is 12 inches, with a bit of wiggle room.

I mainly use this for creating resin art but who’s to say you couldn’t make chocolate sculptures or really anything else that would build up as the mold rotates! I’ve been creating monster toys and sculptures for well over two decades (yes I’m old) and this is a tool I wish I had on many projects and many years ago!"

John Pinkerton

The Monster Sandbox

Share